U.S. President Donald J. Trump’s theory of the case, when it comes to imposing significant new tariffs, is that it will reduce trade deficits, and stop China from “ripping us off” and “taking advantage of us.”

But another frequent defense of the tariffs is that they will force “reshoring,” and will encourage American companies to move their manufacturing and supply chains back stateside, therefore putting into place a renaissance in domestic manufacturing that would create lots of jobs.

However, there are reasons to doubt whether the tariffs, even if applied consistently and without ambiguity — which, it’s clear, they have not been — would lead to a return of American manufacturing. But there are many complications to building a brand new supply chain- and the biggest obstacle to doing so is cost.

Tariffs and Surveying the Supply Chain

According to the latest CNBC Supply Chain survey, most companies say that high costs will prevent them from moving manufacturing back to the U.S.- and if they did, “81% expect automation to be favored over workers,” which would seem to undercut the idea of tariffs leading to a surge in new manufacturing jobs.

Also, many surveyed say that rather than bring manufacturing to the U.S., the tariffs will likely cause the manufacturers to look for other places to put their factories, and to “kick off a new global search for low-tariff regimes.”

Those surveys also predicted that price hikes are coming and that 63 percent of respondents believe that recession to the “base case.”

In the survey, 75 percent of those answering said cost was the biggest reason why they wouldn’t reshore manufacturing. “The challenge of finding skilled labor” was the answer given by 21 percent.

A majority of those answering the survey also agreed that moving its supply chain to the U.S, would take many years.

What product categories would be hurt most by the tariffs? According to the survey, those are discretionary products (44 percent), furniture (19 percent), and luxury (19 percent).

A Domestically-Made iPhone?

The iPhone is an example of a popular product, made by an American company (Apple) but made and assembled through an extremely complex supply chain with components all over the world.

Trump and his spokespeople have mused on the idea of Apple building the iPhone in the United States. And Trump has long had a cordial relationship with Apple CEO Tim Cook, even during his first term when Trump frequently feuded with tech CEOs.

But even after Apple announced a $500 billion commitment to spend in the United States in the next four years, and after the tariffs on China, the appearance of an exemption for consumer electronics products, and Trump’s denial that he’d made such an exemption, it’s unlikely that Apple will commit, anytime soon, to moving the iPhone supply chain to the U.S.

“The reality is it would take three years and $30bn in our estimation to move even 10% of its supply chain from Asia to the US with major disruption in the process,” Daniel Ives of Wedbush Securities, a financial analyst who has frequently appeared in the media to discuss the tariffs, said in a recent note to investors.

Mark Gurman, who frequently covers Apple for Bloomberg News, also described why such a move is unlikely. The U.S. simply lacks the logistical infrastructure to produce iPhones and the supply chain that makes that production possible, at the scale that is necessary.

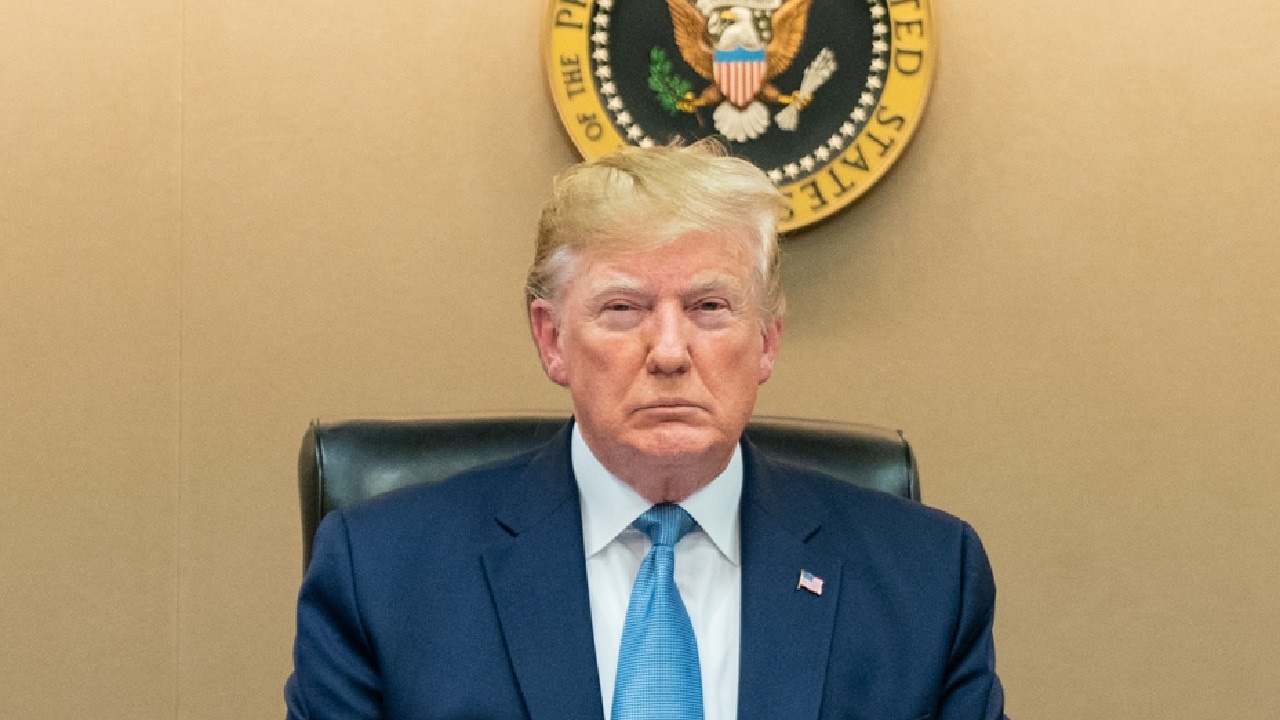

President Donald J. Trump is joined by Vice President Mike Pence, National Security Advisor Robert O’Brien, left; Secretary of Defense Mark Esper and Chairman of the Joint Chiefs of Staff U.S. Army General Mark A. Milley, right, Saturday, Oct. 26, 2019, in the Situation Room of the White House monitoring developments as U.S. Special Operations forces close in on notorious ISIS leader Abu Bakr al-Baghdadi’s compound in Syria with a mission to kill or capture the terrorist. (Official White House Photo by Shealah Craighead)

Matthew Moore, a former Apple engineer, told Bloomberg that “millions of people” work on the Apple supply chain in China, the kind of thing that would not be easy to replicate in the U.S.

“Boston is over 500,000 people,” Moore told Gurman in the story. “The whole city would need to stop everything and start assembling iPhones.”

Apple is also, per Gurman, looking to make India, rather than China, a major site for iPhone manufacturing.

About the Author: Stephen Silver

Stephen Silver is an award-winning journalist, essayist and film critic, and contributor to the Philadelphia Inquirer, the Jewish Telegraphic Agency, Broad Street Review and Splice Today. The co-founder of the Philadelphia Film Critics Circle, Stephen lives in suburban Philadelphia with his wife and two sons. For over a decade, Stephen has authored thousands of articles that focus on politics, technology, and the economy. Follow him on X (formerly Twitter) at @StephenSilver, and subscribe to his Substack newsletter