Key Points and Summary: Visible rust on US Navy warships has reportedly drawn sharp criticism from President Trump, demanding Navy Secretary John Phelan “fix the damn rust.”

-Navy officials explain the rust is primarily a consequence of the fleet’s unparalleled high operational tempo globally and constant exposure to corrosive saltwater, which wears down protective coatings on steel hulls.

-While crews conduct continuous preservation, efforts are constrained by operational demands, environmental regulations limiting maintenance activities, and shipyard capacity.

-Unlike lower-tempo navies, the US fleet’s appearance reflects intense use, though officials maintain the ships remain fully mission capable despite cosmetic issues.

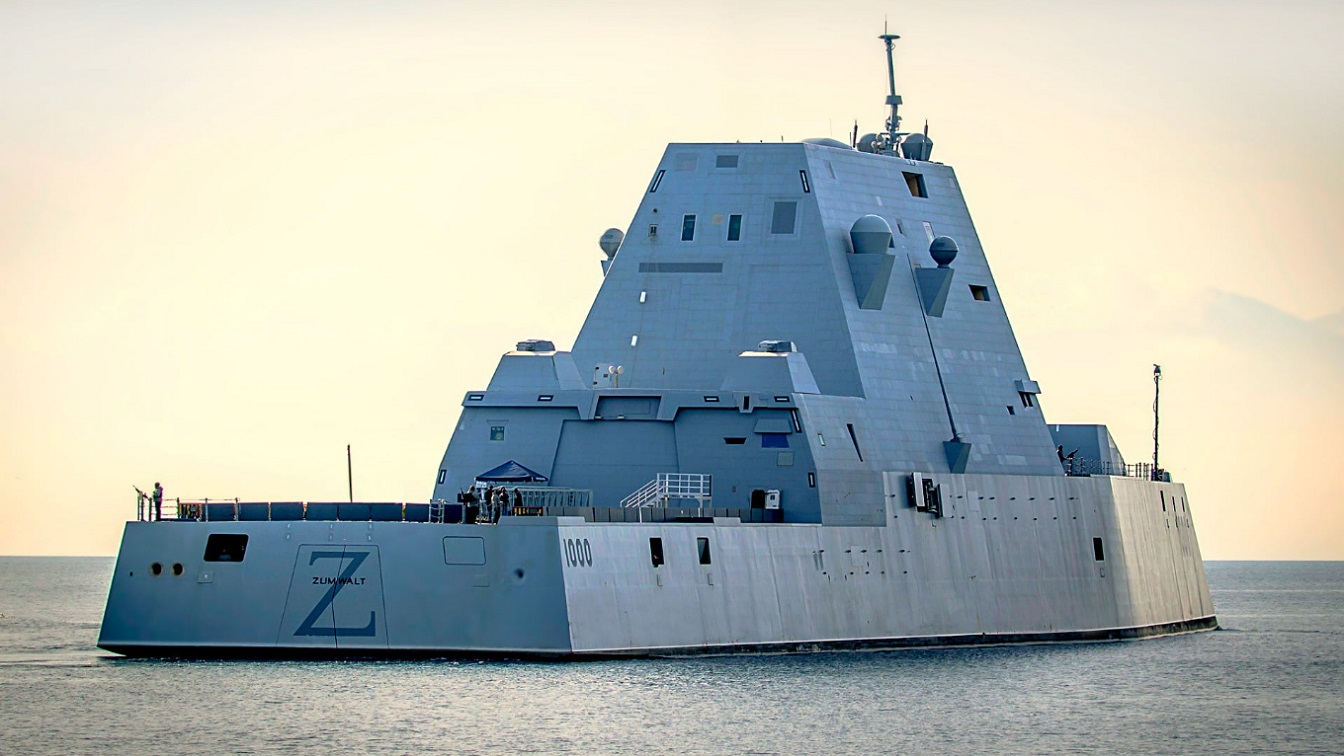

Is The US Navy Getting Too Rusty?: The US Navy has a rust problem, and it has gotten the attention of President Trump. The president has been leveling criticism at Navy Secretary John Phelan about US ships appearing to be “running rust,” and he’s been texting Phelan late at night.

The U.S. Navy’s Rust Problem

“I jokingly say President Trump has texted me numerous times very late at night, sometimes after one o’clock in the morning, about ‘rusty ships or ships in a yard, asking me what I am doing about it,” Phelan said.

The rusty appearance of Navy warships reflects real wear and tear that requires maintenance attention.

Rust and corrosion, which are exacerbated by persistent exposure to saltwater, can cause serious problems with structural integrity and other issues, something the Navy does not deny.

Russian And Chinese Ships Seem Pristine, Why Doesn’t the US?

Appearances can be quite different from reality. Neither China’s nor Russia’s Navy comes remotely close to the operational tempo (OPTEMPO) that the US Navy regularly conducts.

Take the operation in Yemen, bombing the Houthi terrorist missile sites and troop concentrations. A carrier strike group (CSG) will operate there for six to eight months.

Naval News sent an inquiry to NAVSEA (Naval Sea Systems Command) asking why U.S. Navy ships have appeared so rusty recently.

NAVSEA’s Jamie Koehler sent a reply.

“The U.S. Navy has an inherently high operational tempo [around the world]. The vast majority of Navy ships are made of steel, which incurs corrosion from exposure to seawater.

“As such, any scratches or wear in coatings that expose steel on ships will result in corrosion and rust staining. It’s essential to note that for our ships and crews, shipboard preservation is a constant process. Our crews devote considerable time and effort to preserving and maintaining the interior and exterior areas of ships while balancing operational requirements and adhering to Navy shipboard procedures and environmental regulations.

We take a methodical approach to preserving our ships, synchronizing efforts with other maintenance requirements to ensure ships are ready and fully mission capable.”

The U.S. Navy operates on an unparalleled global scale, maintaining a presence in virtually every significant body of water around the world.

This extensive reach comes with an incredibly demanding operational tempo. American warships routinely embark on deployments lasting six to eight months, and in some cases, even longer.

Environmental Factors:

Exposure to saltwater is a major contributor to corrosion and has been the bane of sailors since the very first ironclad warship. Even with protective coatings, saltwater can penetrate cracks and crevices, causing rust.

Sunlight and Extreme Temperatures:

These can accelerate the deterioration of paints and other protective coatings, leading to increased rust rivers on board ships. Even with protective paints and coatings, they can still be damaged by wear and tear during long deployments and exposure to environmental factors, which can lead to corrosion of the underlying steel.

Anti-Corrosion Work Isn’t Easy, There Are Many Rules and Regs:

Municipal, state, and federal environmental regulators have cracked down nationwide on once-routine efforts to scrape rust, maintain equipment, and repaint vessels and aircraft.

Commanding officers have learned to schedule specific types of anti-rust work at specific places, and the maintenance will take place only under calm weather conditions.

“Shipboard preservation never stops,” USS Benfold’s then-commanding officer, Cmdr. Marcus Seeger said in a statement to Navy Times. “Our crews devote considerable time and effort to preserving and maintaining the interior-exterior areas of ships while balancing operational requirements and adhering to Navy shipboard procedures.”

Secretary John Phelan repeated that he has a mandate from President Trump: “Fix the damn rust.”

“He has stated to me many times: ‘Shipbuilding, shipbuilding, shipbuilding. Get those ships out of maintenance yards. Fix the damn rust,’” Phelan said earlier this month. “He does not like it, and I don’t like getting calls in the middle of the night.”

The Navy needs more shipyard help, which would speed up the rust work parties. Otherwise, Secretary Phelan’s phone is going to ring in the middle of the night. And he doesn’t want to take that call.

About the Author:

Steve Balestrieri is a 19FortyFive National Security Columnist. He served as a US Army Special Forces NCO and Warrant Officer. In addition to writing for 19FortyFive, he covers the NFL for PatsFans.com and is a member of the Pro Football Writers of America (PFWA). His work was regularly featured in many military publications.